In the industrial world, packaging solutions play a crucial role in protecting products during storage and transit. Machine shrink wrap is a popular choice for many industries due to its efficiency, versatility, and protective properties. This guide explores the different types of machine shrink wraps available and their applications, helping you make an informed decision for your packaging needs.

Types of Machine Shrink Wraps

1. Polyolefin (POF) Shrink Wrap

Polyolefin shrink wrap is widely used due to its versatility and superior strength. It is known for its clear and glossy finish, which enhances product visibility and appeal. Polyolefin shrink wrap is puncture-resistant and can conform to irregular shapes, making it suitable for various industries, including food, pharmaceuticals, and retail.

Advantages:

-

Strong and durable

-

High clarity and gloss

-

Safe for direct food contact

-

Resistant to punctures and tears

2. Polyvinyl Chloride (PVC) Shrink Wrap

PVC shrink wrap is another common choice for industrial packaging. It offers good clarity and is generally less expensive than polyolefin. PVC is more rigid and can provide a tight, secure seal around products. However, it is less flexible and may not be suitable for all applications.

Advantages:

-

Cost-effective

-

Clear and glossy finish

-

Excellent for retail packaging

-

Good protection against moisture and dust

3. Polyethylene (PE) Shrink Wrap

Polyethylene shrink wrap is known for its strength and durability, making it ideal for heavy-duty applications. It is commonly used for bundling multiple items together, such as bottles or cans. PE shrink wrap is less clear than POF or PVC but offers superior protection for large and heavy products.

Advantages:

-

High durability and strength

-

Suitable for heavy-duty applications

-

Effective for bundling multiple items

-

Provides excellent protection against impacts

Choosing the Right Machine for Shrink Wrapping

When it comes to applying shrink wrap, the type of machine used can significantly impact efficiency and effectiveness. An auto shrink wrap machine is a valuable investment for industries looking to streamline their packaging process. Here are the main types of shrink wrap machines to consider:

1. L-Bar Sealers

L-bar sealers are versatile machines that create a seal around the product using a single piece of shrink film. They are suitable for small to medium-sized products and can be used with both PVC and polyolefin films. These machines are ideal for businesses looking for a cost-effective solution with moderate production volumes.

Advantages:

-

Versatile and easy to use

-

Suitable for various film types

-

Cost-effective for small to medium production runs

2. Chamber Machines

Chamber shrink wrap machines enclose the product in shrink film and heat-shrink it in a single chamber. These machines are compact and easy to operate, making them suitable for small businesses or those with limited space. Chamber machines are typically used for packaging smaller items and offer a neat, professional finish.

Advantages:

-

Compact and space-saving

-

Easy to operate

-

Provides a professional finish

3. Heat Tunnels

Heat tunnels are used in conjunction with L-bar sealers or other sealing machines. After the product is sealed in shrink film, it passes through a heat tunnel, which applies heat evenly to shrink the film tightly around the product. Heat tunnels are ideal for high-volume production and can handle larger products.

Advantages:

-

Suitable for high-volume production

-

Provides consistent and even shrinking

-

Can handle larger products

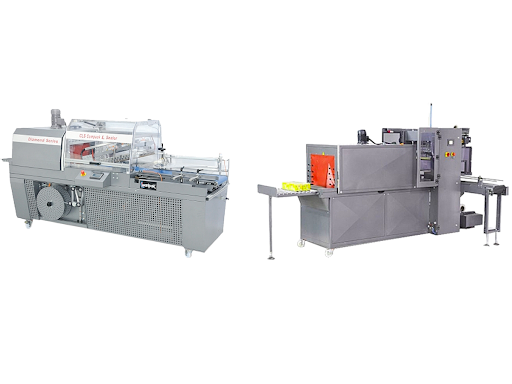

4. Auto Shrink Wrap Machines

Auto shrink wrap machines are fully automated systems designed for high-speed production environments. These machines handle the entire shrink-wrapping process, from sealing to shrinking, with minimal manual intervention. Auto shrink wrap machines are ideal for industries with high packaging demands and can significantly improve efficiency and throughput.

Advantages:

-

Fully automated for high-speed production

-

Minimal manual intervention required

-

Ideal for large-scale operations

Applications of Machine Shrink Wraps in Industries

Machine shrink wraps are used across various industries due to their protective and aesthetic benefits. Here are some common applications:

1. Food and Beverage

Shrink wrap is widely used in the food and beverage industry for packaging items like bottled beverages, canned goods, and perishable foods. The protective film helps extend shelf life by protecting products from moisture and contaminants.

2. Pharmaceuticals

In the pharmaceutical industry, shrink wrap provides a secure and tamper-evident seal for medications and medical supplies. This ensures product integrity and safety during storage and transportation.

3. Retail

Retail products benefit from the clear, glossy finish of shrink wrap, which enhances product visibility and appeal. It is commonly used for packaging items like DVDs, electronics, and cosmetics.

4. Manufacturing

Manufacturing industries use shrink wrap for bundling and protecting products during shipping. Polyethylene shrink wrap is particularly useful for heavy-duty applications, ensuring that products remain secure and protected from damage.

Conclusion

Understanding the different types of machine shrink wraps and their applications can help you choose the best packaging solution for your industry. Whether you opt for polyolefin, PVC, or polyethylene, selecting the right material and machine, such as an auto shrink wrap machine, is essential for efficient and effective packaging. By investing in the appropriate shrink wrap solution, you can enhance product protection, improve operational efficiency, and present your products professionally.