Screw vacuum pumps are a critical component in many industrial applications. They are valued for their efficiency and reliability. One of their key benefits is energy efficiency, which is essential in today’s environmentally conscious world. This article delves into the energy efficiency of screw vacuum pumps, providing you with essential information to optimize their use.

Understanding Screw Vacuum Pumps

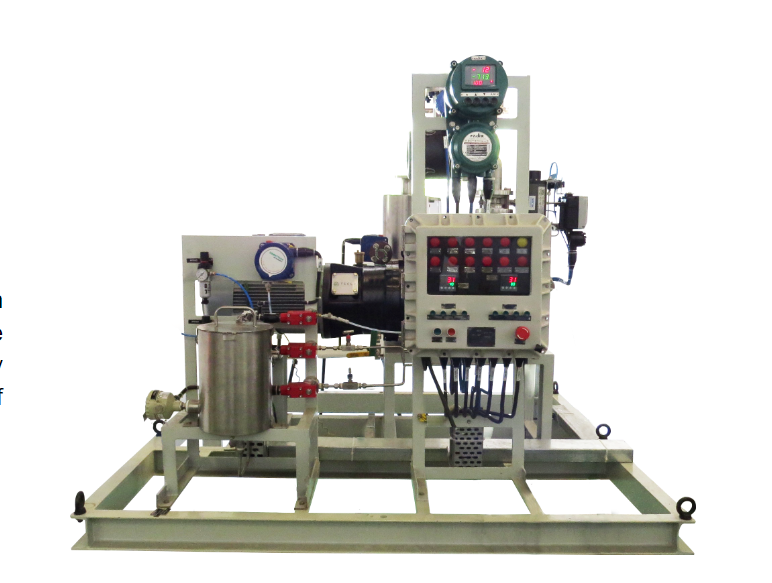

Two intermeshing screws are used in screw vacuum pumps’ operation to compress and transfer gas. Since these pumps run dry, they don’t need water or oil for lubrication or sealing. This design lowers the need for maintenance and contamination. Screw vacuum pumps can also effectively handle a wide range of gases and vapors due to their versatility.

The fundamental working concept of a screw vacuum pump is simple. The gas is trapped and compressed between the screws as they rotate in opposing directions. The compressed gas is released at the pump’s outlet as it travels along the screws. This seamless, ongoing process results in effective operation.

Energy Efficiency: Why It Matters

Reducing operating expenses and minimizing environmental effects need energy efficiency. Energy costs account for a sizable amount of operating costs in many sectors. Enhancing energy efficiency can result in significant cost savings for organizations. Energy-efficient technology also helps achieve environmental objectives by cutting greenhouse gas emissions.

Screw vacuum pumps are renowned for operating with minimal energy consumption. When compared to other kinds of vacuum pumps, they use less electricity. Their dry-running architecture and the screw mechanism’s accuracy are the reasons for their efficiency. Furthermore, they are the best option for many applications due to their capacity to withstand a range of loads without experiencing appreciable energy loss.

Factors Affecting Energy Efficiency

Screw vacuum pumps’ energy efficiency is affected by several things. By being aware of these variables, pump performance may be maximized and energy usage can be decreased.

- Pump Design: The screw vacuum pump’s energy efficiency is largely determined by its design. Cutting-edge technology is used in contemporary designs to reduce energy loss. Features like variable speed drives (VSDs) enable the pump to change its speed in response to the load, saving energy that isn’t needed.

- Maintenance: Maintaining screw vacuum pumps’ energy efficiency requires routine maintenance. The performance of the pump may be impacted over time by wear and tear. The optimal efficiency of the pump is ensured through routine maintenance. This includes replacing worn-out components, cleaning the screws, and looking for leaks.

- Operating Conditions: The energy efficiency of the pump is also affected by its working conditions. Performance can be impacted by variables like temperature, pressure, and the type of gas being pumped. To preserve efficiency, it is critical to keep an eye on these circumstances and make the required modifications. For example, keeping the pump running within its suggested temperature range helps save energy and avoid overheating.

- Load Variations: Screw vacuum pumps are made to effectively handle a range of loads. On the other hand, notable variations in load can affect energy efficiency. Optimizing performance may be achieved by selecting a pump that meets the needs of the application. Using VSDs can also aid in better managing load changes and preserving energy efficiency.

Benefits of Energy-Efficient Screw Vacuum Pumps

Screw vacuum pumps that use less energy have many advantages for both businesses and the environment.

- Cost Savings: The main advantage is financial savings. Pumps that are energy-efficient use less energy, which results in less electricity costs. Energy-efficient pumps can result in significant cost savings over time, making them an investment that is well worth making.

- Reduced Environmental Impact: Energy-efficient screw vacuum pumps help lower greenhouse gas emissions by using less energy. This is compliant with both legal standards and sustainability aims. By using energy-efficient technologies and showcasing their dedication to environmental responsibility, businesses can improve their reputation.

- Improved Performance: Screw vacuum pumps that use less energy frequently function better and are more reliable. They have lower maintenance costs and downtime since they are less likely to overheat and experience mechanical breakdowns. In industries where uninterrupted operation is vital, this dependability is critical.

- Longevity: Longer-lasting pumps are often those that use less energy. Extended service life is a result of optimized operation’s decreased wear and tear. Because of their lifetime, they require fewer repairs and have lower replacement expenses.

Tips for Optimizing Energy Efficiency

Screw vacuum pump energy efficiency can be increased by taking a few useful actions.

- Regular Maintenance: It is imperative to put in place a regular maintenance routine. This entails checking the pump, sanitizing parts, and changing out worn components. Frequent maintenance keeps the pump operating at maximum efficiency and guards against energy loss from mechanical problems.

- Use of Variable Speed Drives: Screw vacuum pumps benefit greatly from the addition of variable speed drives. By enabling the pump to modify its speed in response to the load, it minimizes needless energy usage. VSDs can greatly increase energy efficiency by adjusting the pump’s speed to the demands of the application.

- Monitoring Operating Conditions: It is essential to keep an eye on the pump’s working conditions to preserve energy efficiency. This involves monitoring the composition of the gas, pressure, and temperature. Optimizing performance and lowering energy usage can be achieved by making the required modifications depending on these criteria.

- Proper Sizing: It is crucial to choose the appropriate pump size for the given application. While an undersized pump might not be able to meet the needs of the application, an oversized pump can result in energy waste. The efficient operation of the pump and its ability to meet process demands are guaranteed by proper size.

- Energy Audits: Finding areas for improvement might be aided by routinely conducting energy audits. These audits evaluate the performance and energy usage of the pump and offer insights into possible efficiency improvements. By putting energy audit suggestions into practice, performance can be increased and costs can be significantly reduced.